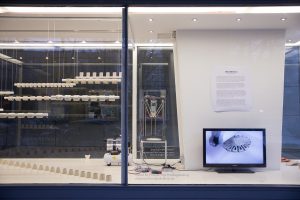

Bachelorproject by Daniel Valencia Ferrá

The digitalisation of the Industry is influencing the way in which traditional materials are being taken into form. Ceramic materials like clay, earthenware, stoneware, grog and porcelains have been until now hand modelled, thrown at the potter´s wheel and cast moulded. Additive manufacturing processes are proposing a fourth way to give form to ceramic materials. The Internet and Social Media are generating an interconnected society, in which the access and distribution of information are rapidly accelerating. This phenomenon is allowing makers, the construction and personalisation of complex high-end technology projects, by assembling simple different knowledge building blocks from different sources.

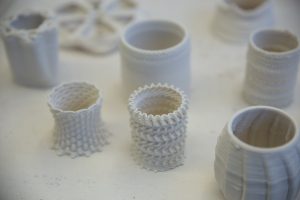

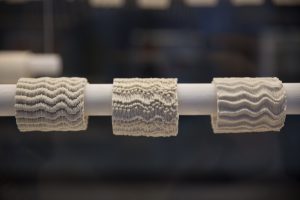

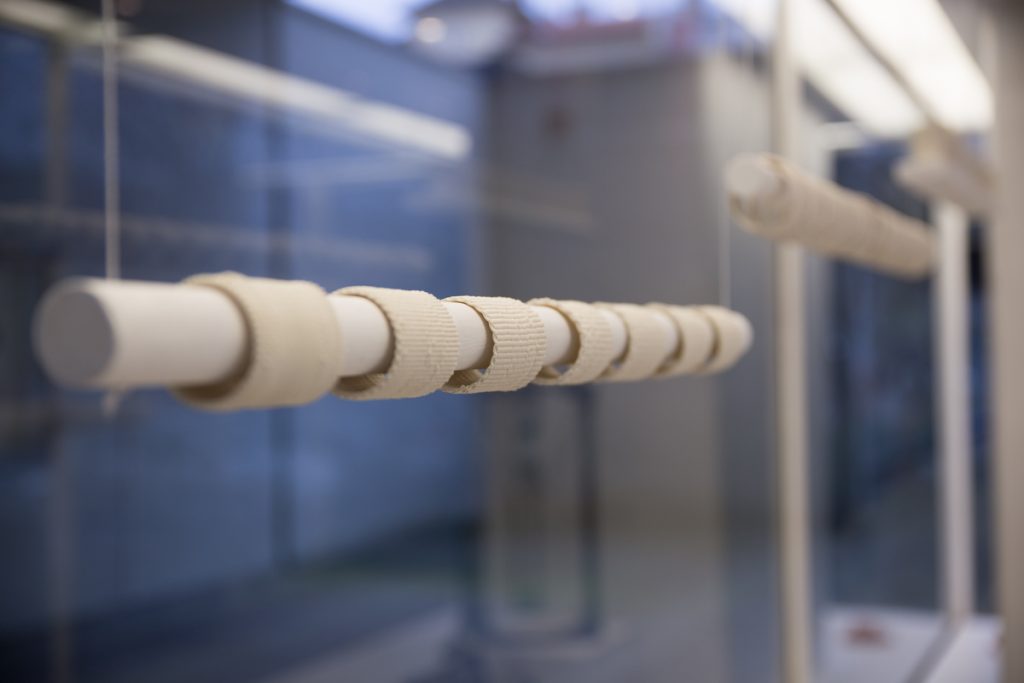

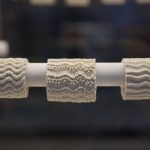

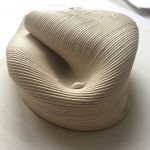

Sora, a desktop paste printer is born out of the will, to have full access and management over a 3D clay additive process, for experimental and prototyping purposes. The way in which the material is deposited over itself along the different layers generate new morphologies, that differ from other traditional ceramic processes. These outcomes and their eventual functional applications are still to be tested and discussed: In which manner could they enrich the ceramic properties for other industrial fields?

To define the way in which the clay is extruded, I decided to use parametric modelling strategies. The movements of the printing nozzle are defined by different algorithms and script. Some of the printed results differ importantly from the original CAD design and are the result of human intention and computational/mechanical potential. This iterative design process, in which human capabilities and digital technology are combined, creates the foundation of Cerametrics: a digital approach to Craft.

17 November 2017 – 19 January 2018, 24/7

Outside Showcase, UdK Berlin, Einsteinufer 43